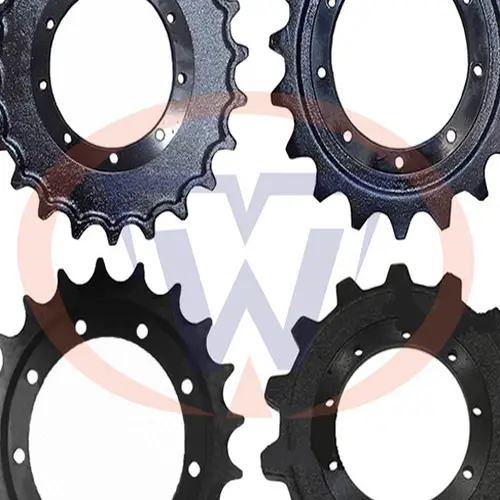

High-Quality CHINAMFG Vio20-2 Vio30 Vio40 Mini Excavator Parts Drive Sprocket

Product Description

Discover the exceptional range of CHINAMFG Vio20-2 Vio30 Vio40 Mini Excavator Parts Drive Sprocket, specifically designed to enhance the performance and longevity of your machinery. Crafted from premium materials and employing advanced manufacturing techniques, these parts ensure durability and reliability in the most demanding environments.

Product Features

| Product Name | Mini Excavator Undercarriage Parts |

| Bundles Include | Top Roller / Track Roller / Idler / Sprocket / Rubber Track / Steel Track Group |

| Raw Material | 35MNB/40MN2 |

| For Machine Type | Mini Excavator / Excavator |

| Manufacture Technique | Forging / Casting |

| Surface Hardness | 56° – 62° HRc; depth: 8mm-12mm |

| OEM/ODM Customize | Fully Supported |

| Certificate | ISO 9001:2000 |

| Ports of Shipment | HangZhou / HangZhou / HangZhou or Any Specific Port In China |

| Dispatch Time | Within 24 Hours |

Compatible Brands and Models

| Brand | Model |

| Kubota | K005 K007 K008 K571 K571 K571 K038 K040 K050 KH007 KH008 KH571 KH571 KH030 KH033 KH040 KH055 KH060 KH101 KH11 KH12 KH14 KH15 KH18L KH20 KH21 KH28 KH30 KH31 KH36 KH37 KH38 KH40 KH41 KH50 KH55 KH60 KH61 KH70 KH71 KH90 KH91 KX007 KX008 KX012 KX019 KX571 KX571 KX033 KX037 KX040 KX055 KX060 KX071 KX080 KX101 KX121 KX161 KX21 KX27 KX28 KX33 KX36 KX40 KX41 KX51 KX57 KX60 KX61 KX71 KX75 KX80 KX90 KX91 U10 U15 U17 U20 U25 U27 U30 U35 U40 U45 U48 U50 U55 U56 |

| Bobcat | X119 X122 X231 X325 X328 X331 X334 X335 X337 X425 X430 E10 E16 E20 E25 E26 E32 E35 E42 E45 E50 E55 E85 E88 |

| Case | 9007 CK08 CK13 CK15 CK16 CK20 CK22 CK25 CK28 CK31 CK32 CK35 CK36 CK38 CK50 CK52 CK62 CK82 CX15 CX16 CX17 CX18 CX23 CX25 CX26 CX27 CX28 CX30 CX31 CX35 CX36 CX37 CX40 CX45 CX47 CX50 CX52 CX55 CX57 CX60 CX75 CX80 |

| Caterpillar | 308 310 E70 E120 E305.5 E307 E311/312 |

| Gehl | Z17 Z25 Z27 Z35 Z45 Z55 Z80 M08 MB138 MB145 MB148 MB253 MB358 GE142 GE152 GE222 GE253 GE272 GE292 GX10 GX35 GE342 GE502 GE12002 G6002RD G6003RD |

| JCB | 802 802.7 804 |

| John Deere | 15 17D 17G 17ZTS 25 26GCAB 27C 27CZTS 27D 27ZTS 30 35C 35CZTS 35D 35G 35ZTS 50CZTS 50D 50DZTS 50GCAB 50ZTS 60GCAB |

| Takeuchi | TB014 TB015 TB016 TB019 TB571 TB035 TB045 TB53 TB125 TB135 TB138 TB145 TB153 TB175 TB180 TB219 TB225 TB228 TB250 TB290 TB235 TB325 |

| Terex | 1305M 1404MK HR1.6 HR16 HR18 HR2.0 HR3.7 TC16 TC20 TC29 TC35 TC35E TC37 TC48 TC50 TC60 TC75 |

| New Holland | 1155R 135SRL 1355RLC E115SR E130 E135B E135SR E145 E160 E165 E175 E175B E175LC EH160LC E195EL E195LC 200SR E200SRLC E215 E215B E215C E215E E215LC E215LCME E235SRLC E235SRNLC E245 E255R E265EL E265LC |

| Yanmar | SV05 SV08 SV09 SV10 SV15 SV16 SV17 SV18 SV20 VIO10 VIO15 VIO17 VIO20 VIO27 VIO30 VIO35 VIO40 VIO45 VIO50 VIO70 VIO75 VIO80 V100 B50 |

| Volvo | EC13BXR EC14 EC15 EC15B EC15C EC15R EC15RB EC15T EC15TB EC15V EC15VB EC15XR EC15XT EC15XTV EC17C EC18 EC18C EC18D EC18E EC20 EC20B EC20BXT EC20C EC20D EC20E EC20XT EC20XTV EC25 EC25X EC27C EC27D EC30 EC30B EC30X EC35 EC35C EC35D EC45 EC45PRO EC50 EC55 EC55B EC55C EC60C EC70 EC75D ECR25 ECR25D ECR28 ECR305CL ECR35D ECR38 ECR40D ECR48C ECR50 ECR50D ECR58 ECR58D ECR88 ECR145DL |

| Hitachi | EX7 EX8 EX10U EX12 EX14 EX15SR HE10 UE004 UE10 UE12 UE15 UE25 CG40 CG45 CG65 CG100 CG110 EX15 EX16 EX17 HE15 ME15 Zaxis16 Zaxis18 ZX16 ZX18 EX15UR EX17U EX21 EX24 EX18-2 EX20 EX22 Zaxis25 ZX25 EX25 EX26 EX27 EX30UR EX29U EX30 EX32U EX33U EX35-2 ZAXIS30 ZAXIS35 ZX30 EX33 EX35 EX40 UE30 EX36U ZAXIS30U-2 ZAXIS35U-2 UE20 UE35 EX45 EX50U EX55 HX140B HX99B UE40 UE45 UE50 ZAXIS40 ZAXIS50 ZX40 ZX50U ZX55U EX58MU ZX50-2 EX60UR EX80 ZAXIS70 EX75UR EX60LC EX70U ZAXIS75US-A ZAXIS40U-2 ZAXIS50U-2 EX100 EX105 ZAXIS110 ZAXIS120 EX120 EX135U EX138UU ZAXIS135US |

| Daewoo / Doosan | DH571 DH35 DH50 DH55 DH60 DH70 DH80 DX17Z DX19 DX27Z DX27Z-7 DX30Z DX35Z DX35Z-7 DX50Z-7 DX55 DX55-9 DX55-9C DX55E DX55R-7 DX57W-5 DX60R DX62R-3 DX63-3 DX63R DX75-5B DX80R DX85R-3 DX89R-7 DX140 SL030P SL035 SL50 SL55 SL75V S055 Solar571 Solar015 Solar018VT Solar30 Solar035 Solar35 Solar55 Solar55V Solar75V Solar130 Solar350 |

| Hanix | H08 H08A H08B H09D H12A H15B H16D H17D H22B H24 H26C H27 H27DR H29 H30 H30C H35 H35A H36B H36C H36CR H36R H45 H50B H50C H55 H55DR H56 H56C H75C N080 N0802 N085UJ |

| Further OEM inquiries | 1) Parts For Models Not Listed Here Can Also Be Fully Customized |

| 2) To Confirm Appropriate Selected Parts For Your Machine | |

| 3) Please contact us for a precise measure-up service |

All manufacturer’s names, symbols & descriptions are used for reference purposes only, and it is not implied that any part listed is the product of these manufacturers.

Other Product Businesses

EVER-POWER GROUP is your trusted partner for a wide array of industrial products. We specialize in agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, and bushings. Our products are known for their superior quality, competitive prices, and exceptional service. We warmly welcome customers to customize drawings and samples to meet their unique needs.

Frequently Asked Questions (FAQs)

1. What materials are used in the manufacturing of the drive sprocket?

The drive sprocket is manufactured using high-quality 35MNB/40MN2 materials, ensuring durability and longevity.

2. How can I ensure the parts will fit my excavator?

Please provide the correct model number, machine serial number, or any numbers on the parts themselves. Alternatively, you can measure the parts and provide us with the dimensions or drawings.

3. What is the delivery time for the mini excavator parts?

FOB HangZhou or any Chinese port: 20 days. If there are parts in stock, our delivery time ranges from 0-7 days.

4. What is the minimum order quantity?

It depends on the product you are purchasing. Normally, our minimum order is one 20′ full container, but LCL (less than container load) is also acceptable.

5. How do you ensure the quality of your products?

We have a comprehensive QC system to ensure perfect products. Our team meticulously inspects each product’s quality and specifications, monitoring every production process until packing is complete to ensure product safety into the container.

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Drive Sprocket

Drive sprockets play a crucial role in the efficient operation of various machinery by transferring rotational motion to linear motion. Here are some key performance characteristics that highlight their importance:

High Durability

Drive sprockets are designed to withstand significant wear and tear. They are often made from robust materials, such as hardened steel, which ensures longevity even under intense conditions.

Precision Engineering

The teeth of drive sprockets are meticulously engineered to ensure seamless engagement with the chain. This precision minimizes the risk of slippage and enhances operational efficiency.

Load Distribution

Drive sprockets are adept at distributing load evenly across the chain, reducing stress on individual chain links and prolonging the lifespan of both the sprocket and the chain.

Resistance to Corrosion

Many drive sprockets are treated or coated to resist corrosion, making them suitable for use in various environments, including those with high moisture or chemical exposure.

Types and Characteristics of Drive Sprocket

Standard Drive Sprockets

These are the most common type, suitable for a wide range of applications. They come in various sizes and configurations to fit different machinery.

Double Pitch Sprockets

Double pitch sprockets feature double the distance between teeth compared to standard sprockets. They are ideal for applications requiring more robust chains and reduced wear.

Split Sprockets

Split sprockets are designed for easy installation and removal without disassembling the chain. This feature makes maintenance more convenient and less time-consuming.

Idler Sprockets

Idler sprockets are primarily used to guide and support the chain, ensuring it remains in the correct position during operation. They do not transmit power but play a vital role in chain longevity.

Material Advantages of Drive Sprocket

Steel Sprockets

Steel is the most common material for drive sprockets due to its exceptional strength and durability. It is suitable for high-load and high-speed applications.

Aluminum Sprockets

Aluminum sprockets are lightweight and resistant to corrosion. They are ideal for applications where weight savings are crucial, such as in automotive and aerospace industries.

Plastic Sprockets

Plastic sprockets are used in applications where low noise and corrosion resistance are priorities. They are commonly found in food processing and packaging machinery.

Applications of Drive Sprocket

Automotive Industry

Drive sprockets are essential components in the automotive industry, used in systems like timing chains and power transmission mechanisms. Their reliability ensures the smooth operation of engines and other critical systems.

Agricultural Equipment

In agricultural machinery, drive sprockets facilitate efficient power transfer, contributing to the performance of equipment such as tractors, harvesters, and irrigation systems.

Construction Equipment

Heavy-duty construction equipment relies on drive sprockets for the reliable operation of machinery like bulldozers, excavators, and cranes. Their durability is critical in harsh environments.

Industrial Machinery

Drive sprockets play a vital role in industrial machinery, ensuring efficient power transmission in conveyor systems, manufacturing equipment, and automated processes.

Marine Applications

In marine environments, drive sprockets are used in various systems, from propulsion to anchor handling. Their corrosion resistance and reliability are essential for maritime operations.

Future Development Trends and Opportunities

The drive sprocket market is poised for significant advancements, driven by innovations in materials science and manufacturing technologies. Here are some key trends and opportunities:

Advanced Materials

Research into advanced materials such as composites and ceramics could lead to sprockets with superior strength-to-weight ratios and enhanced wear resistance.

3D Printing

Additive manufacturing techniques, such as 3D printing, offer the potential for custom sprocket designs with optimized geometries and reduced material waste.

Smart Sprockets

Integration of sensors and IoT technologies could result in “smart” sprockets that monitor wear and performance in real-time, enabling predictive maintenance and reducing downtime.

How to Choose a Suitable Drive Sprocket

Selecting the right drive sprocket involves several considerations to ensure optimal performance and longevity:

Clear Requirements

Identify the specific requirements of your application, including load capacity, speed, and environmental conditions. This information will guide your selection process.

Material Selection

Choose the appropriate material based on the operational environment and performance needs. Consider factors such as strength, weight, and corrosion resistance.

Design Optimization

Opt for a sprocket design that ensures efficient power transmission and longevity. Pay attention to tooth profile, pitch, and alignment.

Suppliers and After-sales Service

Select reputable suppliers who offer high-quality products and reliable after-sales support. This ensures you can address any issues promptly and maintain operational efficiency.

Cost-effectiveness

Evaluate the cost-effectiveness of the sprocket by balancing initial purchase price with longevity and maintenance requirements. A higher upfront cost may be justified by longer service life.

Quality Control

Ensure that the sprockets you purchase meet stringent quality control standards. This minimizes the risk of premature failure and ensures consistent performance.

Conclusion

Drive sprockets are indispensable components in a wide range of applications, from automotive to marine industries. Understanding their performance characteristics, types, and material advantages can help optimize their use. As technology advances, the future holds exciting possibilities for even more efficient and durable sprockets. Making informed choices when selecting sprockets ensures reliable and cost-effective operation across various fields.

Author: Dream